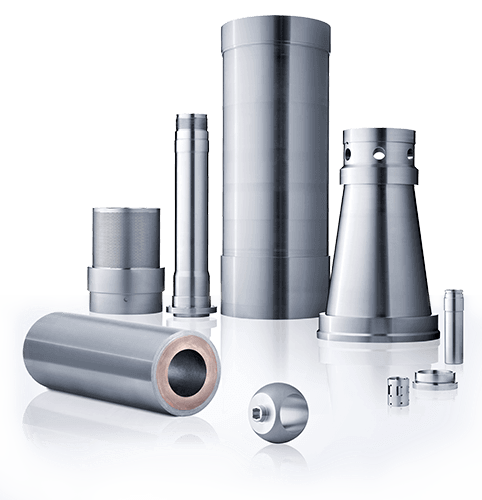

Centrifugal casting

Kuhn Special Steel manufactures exclusively with the centrifugal casting process. This guarantees maximum purity, and better mechanical properties compared to static castings.

During the centrifugal casting process, the liquid steel is poured into a rotating canister and pressed against the outer wall of the canister by the centrifugal forces. After it has been poured in through the centre, the stainless steel is rotated at up to x120 acceleration of gravity. Air bubbles and coarse impurities are therefore driven out by the different densities.

After the steel has been poured in, there is a continual solidification from the outer wall of the canister to the inner surface. More delicate ingredients and slag are driven from the front of the solidification to the inside and can then be processed.

This results in a particularly pure, adjusted structure which is comparable with the forged material in terms of its characteristics. Unlike the forged steel, the characteristics are independent of the direction of load – centrifugal casting does not have any lengthways “fibres”.

Centrifugal casting compared

| Static Casting | Centrifugal Casting |

|---|---|

| solidification under the force of earth gravity, therefore blowholes and impurities remain in the material | solidification under up to 120 times the force of gravity, thereby producing very pure and highly compressed structures |

| mechanical properties are limited upwards | substantially better mechanical properties using the same material (comparable with the values of forged parts) |

| undirected structure, uneven wear | thanks to directional solidification, structure is directed and wear remains even during application |

| patterns required (logistics, pattern costs) | not depending on availability of moulds (moulds from the extensive inventory are used as permanent moulds) |

| within the framework of technical casting restrictions there is a free choice of moulds | no restrictions on certain dimensions, however bound to centric bore hole |

| complicated gating and risering techniques, which have to be taken into account at the time of construction of castings | no ingates, no feeder heads |

| limited selection of materials for each pattern | all materials can be casted (from low alloys to iron-free materials, e.g. Cr-Ni-Mo) |

| special casting techniques, such as bi-metal casting, hardly possible | bi-metal casting possible, for example to create a hard outer layer and ductile inner layer inexpensively |

We would be pleased to answer your questions on the subjects of stainless steel casting, centrifugal casting and composite casting, along with the machining of stainless steel and the manufacture of components to your own precise specifications, including items for decanter construction, shipbuilding, engine manufacture and much else besides.

Just call us on

+49 (0)2195 671-0

infonothing@kuhn-edelstahl.com