Materials

Summary of Kuhn Special Steel High Performance Materials

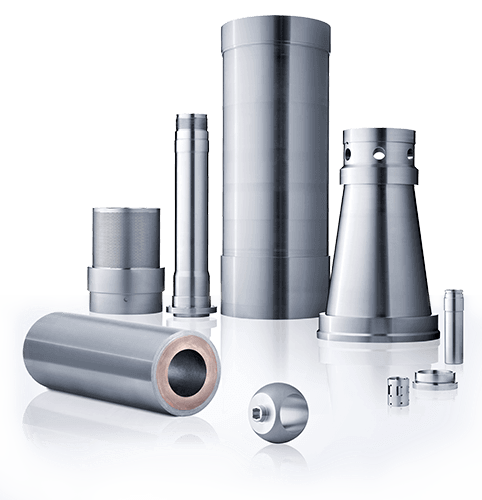

Our foundry deals mainly with high-alloy-content casting materials. Our product portfolio likewise includes a considerable number of low-alloy-content steels for tools (cold, warm and high-speed) and RSH steels. The items concerned range from low-alloy, corrosion-resistant martensitic and soft martensitic alloys to likewise corrosion-resistant duplex alloys (lean, standard and super-duplex grade) and high-alloy, Fe- and Ni-based fully austenitic alloys. These high-alloy-content materials are used in applications that demand maximum resistance to corrosion and/or high temperatures, thereby allowing us to supply a wide selection of application-specific alloys suitable for use in an equally wide range of industrial sectors and market segments.

The equivalent cast alloys of these forged alloys are only rarely standardised. The corrosion resistant nickel cast alloys have norms under the American rules and regulations. No national specifications are in place for the heat resistant nickel cast alloys. Materials are therefore either itemised in our materials list using the ASTM designation or one given internally by our company.

These items below represent just a small selection of our high-performance materials. You can download a fully detailed list of these materials on the right. We are gladly at your disposal to provide you with any further information or advice on specific applications that you might require.

Corrosion-resistant nickel alloys

M-35-1 [N 24135]

A nickel-copper alloy with high strength and excellent corrosion resistance against a wide variety of acidic and other corrosive conditions, particularly suited for use in reduced atmospheres. It also has good ductility and heat conductivity. The application areas include marine engineering, processing equipment in the chemical and petrochemical industries, heat exchangers, valves and pumps.

N-12MV and N-7M [N 30012 and N 30007]

These alloys are part of the group of highly corrosion resistant nickel-molybdenum alloys. The materials are characterised by very good resistance in reduced media, e.g. in hydrochloric acid at all concentrations and temperatures.

CW-2M and CX2MW [N 26455 and N 26022]

These nickel-chromium-molybdenum alloys are characterised by their excellent resistance in oxidised and reduced media, even at higher temperatures. The alloy CX2MW [N 26022] provides good resistance to wet media, e.g. sulphuric acid, phosphoric acid, nitric acid, chlorine gas, acid mixtures of sulphuric acid and oxidised acids with chloride ions. A particular characteristic of this alloy is its high resistance to crevice, hole and stress corrosion at high temperatures under oxidised and reduced conditions.

CW-6MC [N 26625]

A nickel-chromium-molybdenum alloy with niobium, which together with the molybdenum strengthens the matrix, thus ensuring a high strength without heat treatment. It is used in chemical engineering and environmental protection plants.

Heat-resistant nickel alloys

K 617

K617 is a nickel-chromium-cobalt-molybdenum alloy with an excellent combination of structural stability, strength and oxidisation resistance at high temperatures. Its resistance to oxidisation is further increased by adding aluminium. Typical applications are components for combustion chambers and pipes for petrochemical engineering, for heat treatment equipment and for the production of nitric acid.

K 718

An age-hardened nickel-chromium alloy with considerable content of iron, niobium and molybdenum combined with aluminium and titanium contents. Combines corrosion resistance and high strength with very good weldability. The alloy has very good creep strength at temperatures up to 700 °C. Used in gas turbines.

We would be pleased to answer your questions on the subjects of stainless steel casting, centrifugal casting and composite casting, along with the machining of stainless steel and the manufacture of components to your own precise specifications, including items for decanter construction, shipbuilding, engine manufacture and much else besides.

Just call us on

+49 (0)2195 671-0

infonothing@kuhn-edelstahl.com