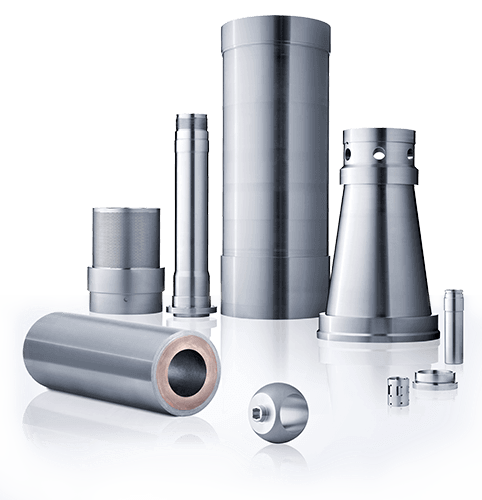

High Performance Key Components

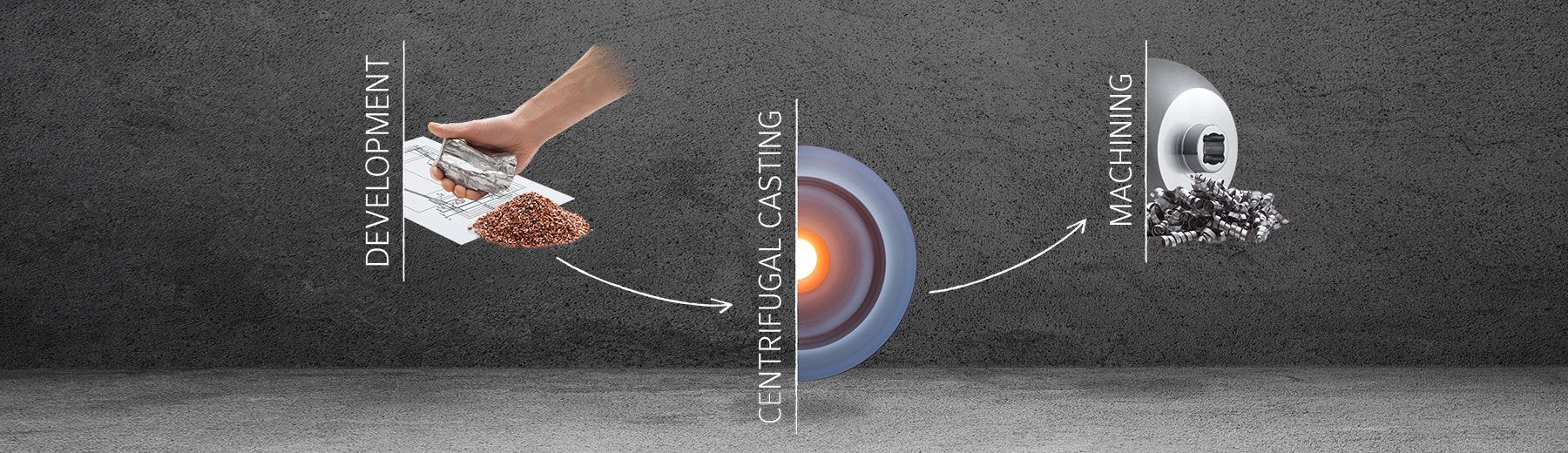

We meet all your needs under one roof, with everything from initial development and raw castings to ready-to-fit components.

Our range of materials includes more than 400 different types of stainless steels and alloys. But we do not just resort to existing standards when looking for the perfect material for your component; we work with you as required to develop a material perfectly matched to your needs.

Our expert materials scientists, design engineers and technicians - all of whom hold advanced qualifications in their respective fields - are likewise on hand to contribute their know-how to the rest of your production process. Thanks to our centrifugal casting process, we are able to offer not only freely dimensioned production in our efforts to meet your needs in this respect, but also highly pure (and therefore extremely resistant) cast structures. The precise contouring of our castings reduces your material costs, while allowing us to produce finished items in accordance with your wishes. The comprehensive nature of our equipment facilities, and the wide range of production that this entails, give us a worldwide lead over other suppliers in the sector. Whether your requirements involve deep-hole drilling, cutting, heavy-duty machining or precision turning on conventional or CNC-controlled lathes; grinding, finishing, milling, honing or highly-efficient UP-welding, we offer you complete solutions from a single source. Our production facilities can also handle welded subassemblies or complete sets of ready-to-install rollers.

Video: The centrifugal casting process

Video: The machining process

We would be pleased to answer your questions on the subjects of stainless steel casting, centrifugal casting and composite casting, along with the machining of stainless steel and the manufacture of components to your own precise specifications, including items for decanter construction, shipbuilding, engine manufacture and much else besides.

Just call us on

+49 (0)2195 671-0

infonothing@kuhn-edelstahl.com