Foundry

Our foundry is equipped with seven medium-frequency induction crucible furnaces with a capacity of 450 kg to 2,100 kg, and a collective capacity of up to 8,500 kg, for the processing of metals.

Output of up to two metric tons per hour guarantees maximum flexibility for individual customer requirements. After the melting procedure, each batch is subjected to a spectral analysis of its composition, and carefully inspected to ensure compliance with the corresponding standards or customer specifications.

Our foundry is equipped with 14 horizontal and 4 vertical centrifugal-casting machines for the processing of molten metal. These can handle horizontally cast components with diameters ranging from 65 mm to 1,200 mm and lengths of between 1,380 mm and 4,500 mm. The vertical casting machines can deal with diameters ranging from 200 mm to 2,500 mm and lengths of between 450 mm and 2,000 mm.

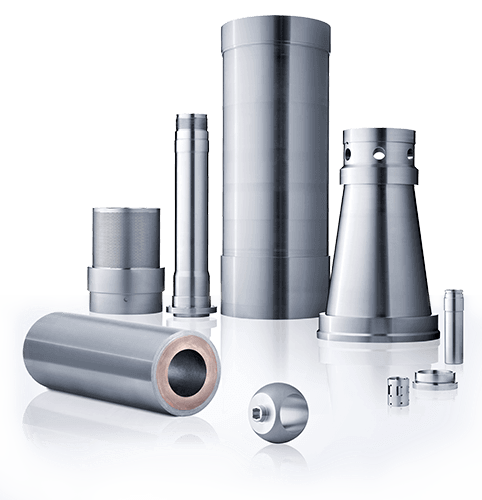

We would be pleased to answer your questions on the subjects of stainless steel casting, centrifugal casting and composite casting, along with the machining of stainless steel and the manufacture of components to your own precise specifications, including items for decanter construction, shipbuilding, engine manufacture and much else besides.

Just call us on

+49 (0)2195 671-0

infonothing@kuhn-edelstahl.com