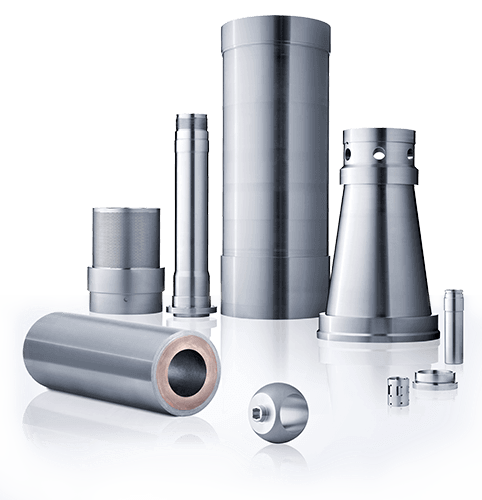

High Performance Key Components for pump and valve construction

High Performance Key Components for pump and valve construction

Pump & valve construction

Pumps

Applications

Industrial technology: Chemicals, surface-finishing technology, food and beverage industry, heat-transfer and refrigeration circuits, processing technology in general, oil and gas sector, marine / energy technology: fossil-fuel power stations, renewable energies, nuclear power stations / water technology: Water drainage, water treatment, water transport / sewage-processing technology: Local-authority sewage and water treatment, transport and treatment of liquid industrial waste / mining : Mining, oil-sand Industry, dredging / building technology: Domestic waste-water disposal, building drainage, heating / air-conditioning / ventilation

Ranges of dimensions

- Outer diameter: min.: 50 mm, max.: 1,500 mm

- Inner diameter: min.: 25 mm

- Maximal cast weight: 3.3 t

- Maximal cast length: 5 m

- Maximal length: 8 m (welded construction)

Components

Thrust rings, split rings, seat rings, shaft seals, spacer seals, motor housing, housing inserts, inlet rings, bottom rings, seal covers

Special requirements of the materials used

Depending on application: high corrosion-resistance, high resistance to wear

Material groups

Duplex steels (standard duplex, super duplex, high-carbon duplex), ferritic and martensite steels, ferritic-carbide gravity castings, austenitic steels, high-temperature ferritic steels

Materials

1.4027 ( 1.4021 ), 1.4138, 1.4308 ( 1.4301 ), 1.4408 ( 1.4401 ), 1.4409 ( 1.4404 ), 1.4309 ( 1.4306 ), 1.4469 ( 1.4410 ), 1.4517, 1.4581 ( 1.4571/1.4580 ), 1.4405 ( 1.4418 ), 1.4059 ( 1.4057 ), 1.4088, 1.4931 (1.4922)*

* Materials listed in italics are those that consist of our material-matched forged alloys

Valves

Applications

Plant construction, chemicals, petrochemicals, long-distance energy, potash industry, power-station technology, food industry, pharmaceuticals, oil industry, cement and construction-material industry, sugar industry, gas supply, water and sewage-treatment, environmental technology

Ranges of dimensions

- Outer diameter: min.: 50 mm, max.: 1,500 mm

- Inner diameter: min.: 25 mm

- Maximal cast weight: 3.3 t

- Maximal cast length: 5 m

- Maximal length: 8 m (welded construction)

Components

Balls, segment balls, seat rings, flanges, perforated-drum driers, twin-ball housings, seal mountings, clamping rings, spacer rings, tubes, bushings

Special requirements of the materials used

Depending on application: Extreme toughness, high resistance to corrosion, high wear-resistance, good welding properties, highly resistance to chemicals, resistance to high and low temperatures, stability when under pressure and high resistance to cavitation

Material groups

Duplex steels (standard duplex, lean duplex, high-carbon duplex, super duplex), austenitic, nickel-based alloys

Materials

1.4470 ( 1.4462 ), 1.4463, 1.4408 ( 1.4401 ), 1.4409 ( 1.4306 ), 1.4308 ( 1.4301 ), 1.4309 ( 1.4306 ), 1.4392 ( 1.4362 ), 1.4469 ( 1.4410 ), J93371 ( 1.4460 ), 1.4468, 2.4836, N26022, N24135, 1.4581 ( 1.4571, 1.4580 )*

* Materials listed in italics are those that consist of our material-matched forged alloys

We would be pleased to answer your questions on the subjects of stainless steel casting, centrifugal casting and composite casting, along with the machining of stainless steel and the manufacture of components to your own precise specifications, including items for decanter construction, shipbuilding, engine manufacture and much else besides.

Just call us on

+49 (0)2195 671-0

infonothing@kuhn-edelstahl.com