Heat treatment

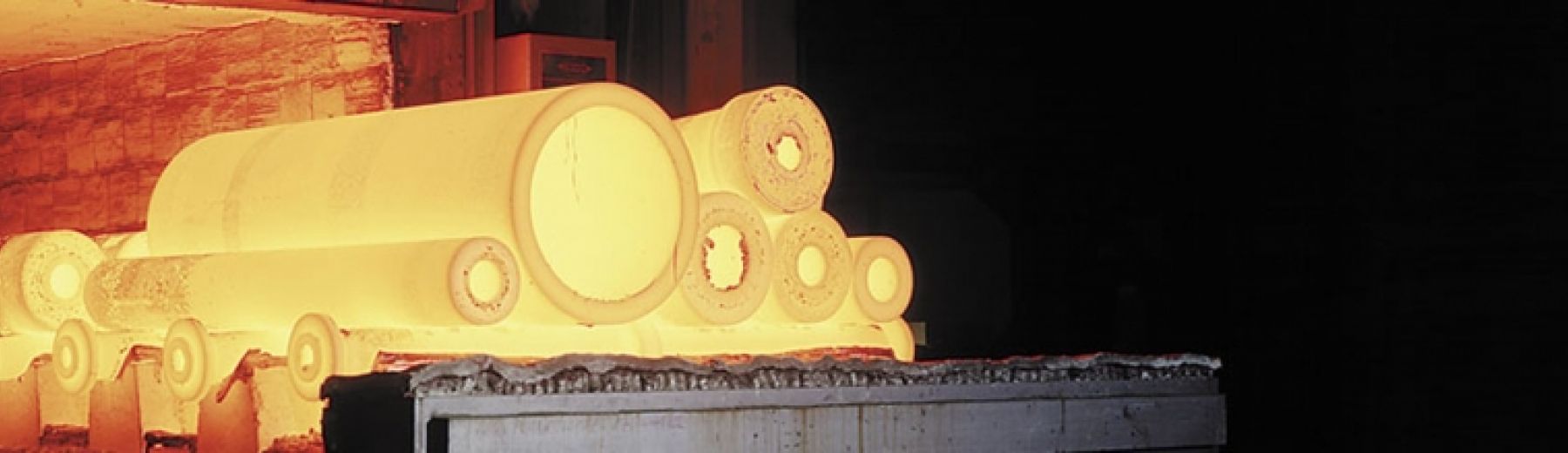

In order to meet exacting specifications, it is not enough just to deliver the right quality; the cast components also have to be subjected to error-free heat treatment.

Depending on the material and its dimensions, the temperature, heating-up time, dwell-time and speed and method of quenching all need to be adjusted in order to deliver optimum results.

Our plant is equipped with seven heat-treatment kilns for this purpose, in shuttle or batch configuration, with a capacity of up to 40 metric tons and a maximum temperature of 1,250 °C. Other facilities include a fully automatic heat-treatment kiln conforming to NORSOK M‑650 standards.

The operations performed include (among others) hardening, tempering, solution annealing and low-stress annealing.

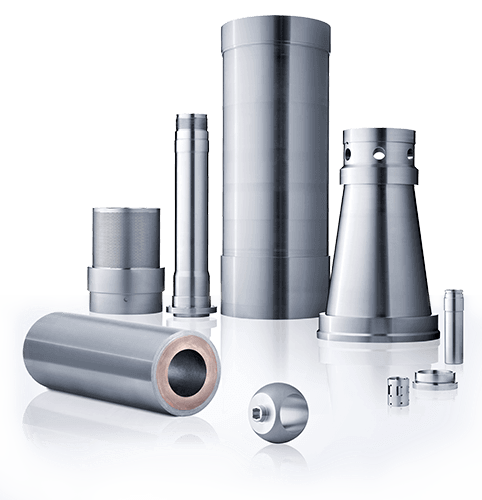

We would be pleased to answer your questions on the subjects of stainless steel casting, centrifugal casting and composite casting, along with the machining of stainless steel and the manufacture of components to your own precise specifications, including items for decanter construction, shipbuilding, engine manufacture and much else besides.

Just call us on

+49 (0)2195 671-0

infonothing@kuhn-edelstahl.com